Polymer: Understanding the Science, Properties, and Applications

Polymer is an integral part of our daily lives, yet many of us may not fully grasp the significance of these remarkable materials. They play a pivotal role in various industries, from packaging and healthcare to electronics and automotive engineering. In this comprehensive article, we will delve deep into the world of polymers, exploring what they are, how they are made, their diverse properties, and their wide-ranging applications.

What is a Polymer?

The Molecular Marvel

At its core, a polymer is a large molecule composed of numerous smaller repeating units called monomers. These monomers link together through chemical bonds, forming a chain-like structure, much like a string of beads. This unique structure gives polymers their distinct properties, making them incredibly versatile materials.

Homopolymers and Copolymers

Polymers can be classified into two primary categories based on their molecular structure: homopolymers and copolymers.

- Homopolymers: These are polymers formed from a single type of monomer. In other words, all the repeating units in a homopolymer are identical. An example of a homopolymer is polyethylene, used in everyday items such as plastic bags and bottles.

- Copolymers: Copolymers, as the name suggests, are composed of two or more different types of monomers. These monomers can be arranged in various ways within the polymer chain, giving rise to different types of copolymers with distinct properties. For instance, the combination of styrene and acrylonitrile results in a copolymer known as ABS (acrylonitrile-butadiene-styrene), commonly used in consumer products like Lego bricks.

Properties of Polymers

Polymers exhibit a diverse range of physical and chemical properties that make them exceptionally valuable materials. Here are some key properties of polymers:

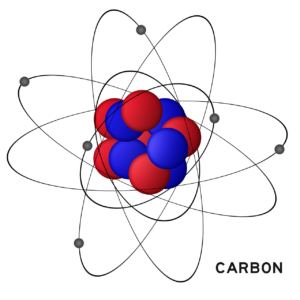

High Molecular Weight

Polymers are characterized by their high molecular weight, meaning they consist of a large number of atoms in each molecule. This attribute contributes to their unique mechanical properties, including high tensile strength and excellent impact resistance. The long, interconnected chains of monomers give polymers their strength and flexibility.

Low Density

Most polymers have low densities compared to metals like steel or aluminum. This low density translates to lightweight materials, making them particularly useful in applications where weight reduction is critical, such as in the aerospace and automotive industries.

Versatility

One of the most remarkable features of polymers is their versatility. By carefully selecting monomers and controlling the polymerization process, engineers and scientists can design polymers with a wide range of properties. This versatility allows for the creation of materials that are flexible, rigid, transparent, opaque, and more.

Chemical Resistance

Many polymers exhibit high chemical resistance, making them suitable for applications where exposure to corrosive substances or harsh environments is expected. For example, polyvinyl chloride (PVC) is known for its resistance to acids, alkalis, and numerous organic solvents.

Electrical Properties

Some polymers possess excellent electrical insulation properties, making them ideal for use in electrical and electronic applications. For instance, polyethylene is commonly employed as an insulator in electrical cables and wiring.

Thermal Properties

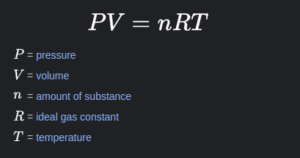

Polymers have a wide range of thermal properties, including varying melting points and glass transition temperatures. This diversity allows for the selection of polymers tailored to specific temperature requirements in applications like food packaging, where materials need to withstand both freezing and heating.

The Science of Polymerization

The process of creating polymers, known as polymerization, is a fundamental aspect of polymer science. Polymerization methods can be broadly categorized into three main types:

Condensation Polymerization

In condensation polymerization, two different types of monomers combine in the presence of a catalyst, forming a polymer chain. A small molecule, often water, is typically released as a byproduct during this process. This type of polymerization is commonly used to produce polymers like nylon and polyester.

Addition Polymerization

In addition to polymerization, a single type of monomer with a double bond (unsaturated monomer) is employed to create a polymer. The double bond is broken, allowing the monomers to link together and form a polymer chain. This method is used to produce polymers such as polyethylene and polypropylene, which are widely used in packaging and plastics manufacturing.

Radical Polymerization

Radical polymerization involves the use of initiators to create highly reactive chemical species known as radicals. These radicals then initiate the polymerization process by bonding with monomers, resulting in the formation of a polymer chain. Polymers like polystyrene and polyvinyl chloride (PVC) are often produced through radical polymerization.

Polymer Applications

The versatility of polymers has led to their extensive use in a myriad of applications across various industries. Let’s explore some of the most notable areas where polymers play a pivotal role:

Packaging

Polymers are ubiquitous in the packaging industry. Materials like polyethylene (both low-density and high-density) are used to create plastic bags, bottles, and containers. Their lightweight nature, durability, and ease of molding make them ideal for preserving and transporting goods.

Healthcare

In the healthcare sector, polymers are utilized in a range of applications, including medical devices, drug delivery systems, and surgical instruments. Biocompatible polymers like polyethylene glycol (PEG) and poly(lactic-co-glycolic acid) (PLGA) are used for drug encapsulation and controlled release.

Automotive

The automotive industry relies heavily on polymers for various components, including bumpers, interior panels, and tires. Polymers offer weight reduction benefits, which can improve fuel efficiency, and they can also be engineered to provide impact resistance and durability.

Electronics

Polymers are indispensable in the electronics sector, where they are used as insulating materials, printed circuit boards (PCBs), and in displays and flexible electronics. Polymers with excellent electrical properties, such as polyimides and polyethylene terephthalate (PET), are chosen for these applications.

Aerospace

The aerospace industry relies on polymers for lightweight materials with high strength and durability. Polymers like carbon-fiber-reinforced composites are used to construct aircraft components, reducing overall weight while maintaining structural integrity.

Construction

Polymers find their way into the construction industry through materials like polyvinyl chloride (PVC) for pipes and fittings, as well as various types of polymer-based coatings for protection against corrosion and weathering.

Textiles and Apparel

Polymers are used in the production of synthetic fibers, including polyester, nylon, and spandex, which are commonly found in clothing, textiles, and sportswear. These synthetic fibers offer durability, elasticity, and resistance to wrinkles.

Environmental

Polymers are also involved in environmental initiatives. Biodegradable polymers like polylactic acid (PLA) are being explored as alternatives to traditional plastics, with the potential to reduce the environmental impact of plastic waste.

The Future of Polymers

The field of polymer science continues to advance, opening up exciting possibilities for the future. Some key areas of development and innovation in polymer technology include:

Smart Polymers

Smart polymers, also known as responsive or intelligent polymers, can undergo reversible changes in their properties in response to external stimuli such as temperature, pH, or light. These materials hold promise in various fields, including drug delivery systems and self-healing materials.

Nanocomposites

Nanocomposites, which combine polymers with nanoparticles, are being researched for their enhanced mechanical, electrical, and thermal properties. These advanced materials have applications in the aerospace, electronics, and automotive industries.

Polymer Additives

The development of new additives and modifiers can enhance the performance and functionality of polymers. These additives can impart properties such as flame resistance, antimicrobial activity, and UV resistance to polymers.

Biodegradable Polymers

In response to environmental concerns, there is a growing interest in developing biodegradable polymers that can break down naturally over time. These materials have the potential to reduce the long-lasting impact of plastic waste on ecosystems.

Polymer Recycling

Efforts to improve polymer recycling methods are gaining momentum. Techniques such as chemical recycling and mechanical recycling aim to reduce the environmental impact of plastics and promote a more sustainable approach to polymer usage.

Conclusion

Polymers are indeed the unsung heroes of the material world, touching nearly every aspect of our daily lives. Their remarkable diversity, from lightweight plastics to high-strength composites, makes them indispensable in numerous industries. As research and innovation in polymer science continue to advance, we can expect even more exciting applications and sustainable solutions to emerge. The future of polymers holds the promise of materials that are not only versatile but also environmentally friendly, contributing to a brighter and more sustainable world.